Material Journey Management System

• Trace Material Location, Status in Real Time

• Geo Tag on Web GIS

• RFID based Material Traceability

• Increased Inventory Visibility

Material Journey Management System

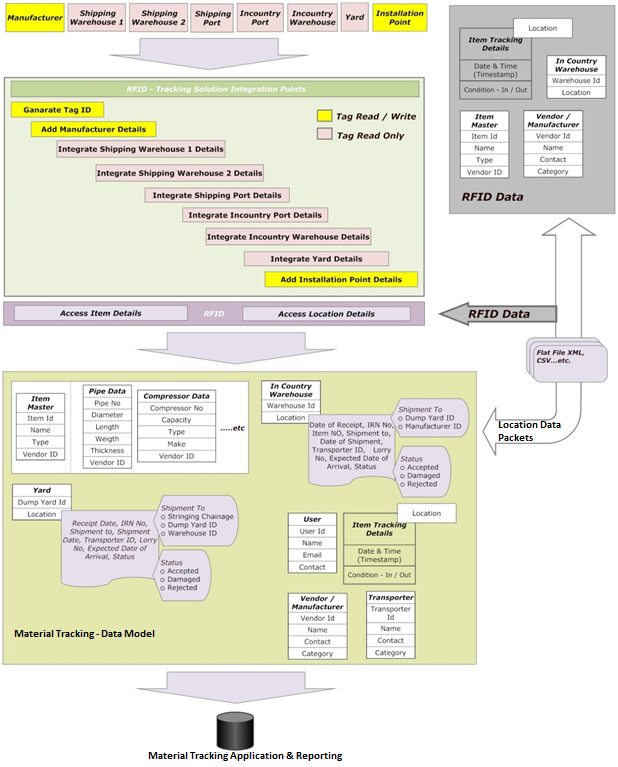

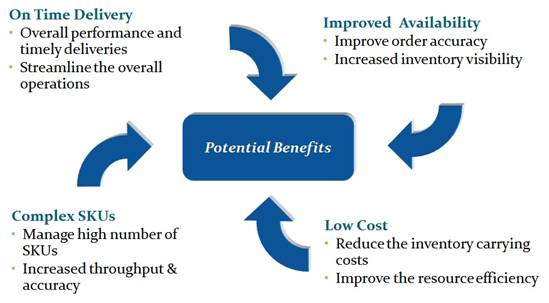

The prominent aim in automation is, overcoming barriers to delivering effective services created by people and surroundings. The process is to be streamlined; services are to become more user-friendly and responsive to user’s needs; and the costs of complying with standard practices to get the data accuracy are to be substantially reduced.

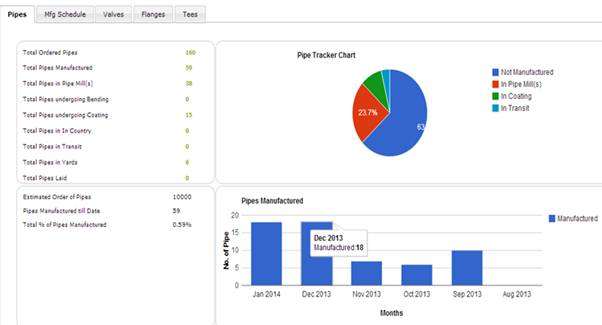

- Material tracking automation allows the display of all information on the screen, along with the graphics, maps and other integrated features like current location of the material, expected date of arrival based on current condition, the available resources and planning. The integrated information at one place allows optimum resource allocation and mobilization.

- Automation will allow the application of modern technologies like RFID, GIS, Remote Sensing and GPS for carrying out cost effective, accurate, data collection, integration, analysis, planning, management and maintenance without human interaction thus reduces the possible errors. The updation of the information will be regularized and the dynamic planning and decision making will be promoted.

- The sharing of technology and information at real time between the different users will become easier and more efficient and repetition of the activities will be avoided saving resources and time of the business functions.

High Value Material Tracking / Pipe Tracking

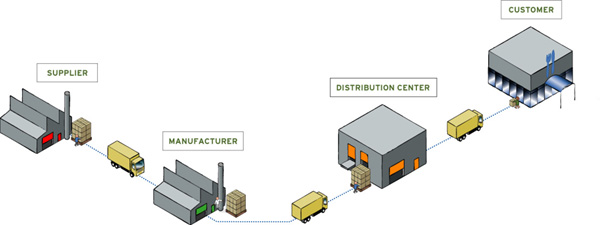

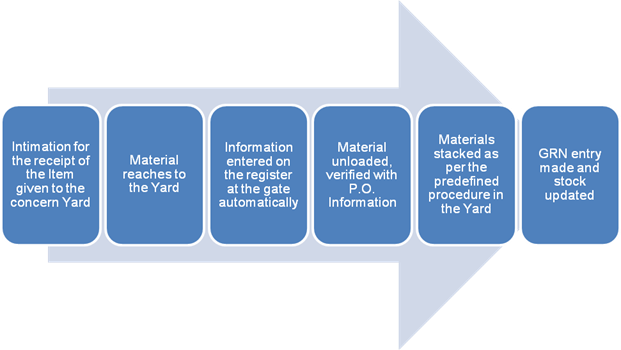

Material received from any vendor globally will be tracked at each location initially the Material tag ID will be generated and that Tag ID will be integrated with new details at vendor location as per the business process requirement. The tag reader/writer will be installed on those places.

The Generated tag data then captured by RFID reader and data will be pushed into local server which will be then pushed into web based PTS system and selective data will be available to users based on their roles.

![]()

The Information received on real-time at different stages will be tracked by reading or writing at each location from material manufacturing till installation point. Selective data will be written inside the RFID Tag and some data will be integrated with the Material Tracking Solution. The information exchange between RFID reader and Tracking Solution will be in the form of flat file like CSV, XML, XLS…etc.

The entire material movement process can be monitored by the users by logging into the web based solution from anywhere any time.

The automation using RFID for Material Tracking has

- Reading / Writing using RFID

- Item Details

- In Country Warehouse Details

- Vendor / Manufacturer Details

- Item Tracking Details

- Integrating Attributes within Solution

- Material Data

- In Country Warehouse Details

- Warehouse Name

- Geo Location

- Receipt Date, IRN No., Transportation Details …etc.

- Shipment Details

- Current Status

- Yard Details

- Yard Name

- Geo Location

- Receipt Date, IRN No., Transportation Details …etc.

- Shipment Details

- Current Status

- Vendor / Manufacturer Details

- Transportation Details

- Item Tracking Details

- Logged in User Details

- The Tag details

- Route optimization

- Provide accuracy in maintenance of records to avoid Manual reading, Read Miss & typing errors

- To enable the data entry directly from the point of activity to Material Tracking Solution.

- To validate the data before entering into PTS and Decrease the multiple data validation time and cost

- To speed up the transaction / physical activity by enabling faster data entry.

- Automate the Verification and authentication on real Online Mode.

- The process will be faster and more efficient

- The current location of the material can be traced and tracked using GPS also geometrical details can be shown on GIS Server.

Way Forward | Scientific Process Improvement Approach

Request a Callback